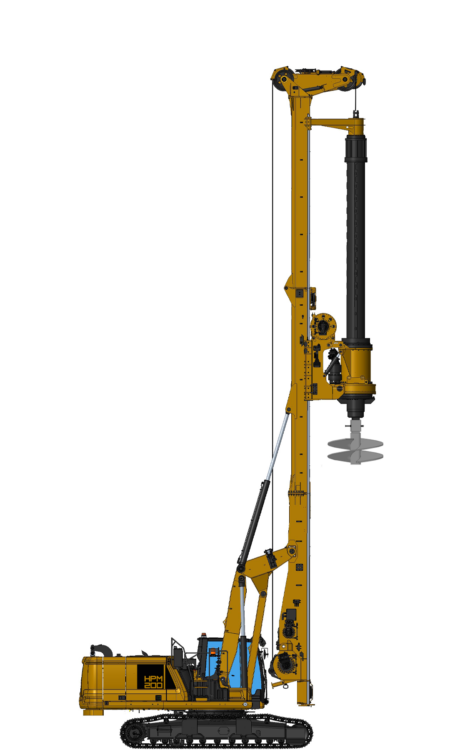

HPM200

| Base | CAT®330 |

|---|---|

| Drilling Depth | 120' ft36 m |

| Drilling Diameter | 2400 mm8' ft inc |

| Operating Weight | 128300 lbf58200 kg |

| Rotary Effective Torque | 185000 lb.ft251 kNm |

Two hundred fifty-one is the torque, the effective torque.

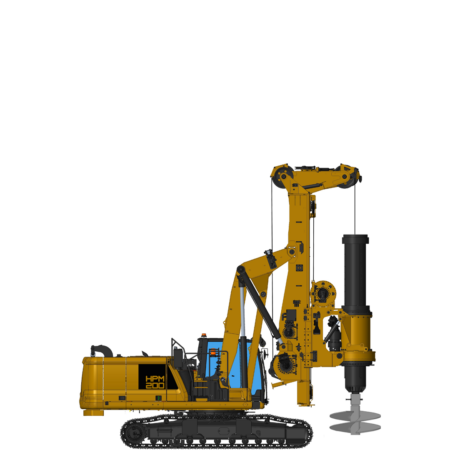

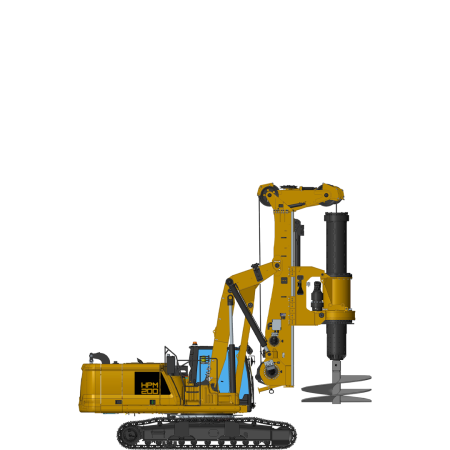

Correct, we don’t think there is much to add. But since we have to fill the page we will also say that it’s modulr design allow you to convert this rig in different configurations, including short mast – 11’ version.

The great stability offered by the expandable undercarriage will also allow to customize the rig in order to install a Crowd Winch System, also suitable for CFA.

HPM200

Two hundred fifty-one is the torque, the effective torque.The HPM200 are mounted on CAT 330 NGH base, equipped with CAT C7.1 engine, which delivers an ISO power of 205 kW (175 KW Fly Wheel) which meets U.S. EPA Tier 4 Final, EU Stage IV, Japan 2014 (Tier 4 Final) and Corea Tier 4 Final with an after-treatment system that does not require maintenance or downtime.

HPM200 Standard can be equipped with long kelly bars allowing to reach great depths while maintaining a compact size.

A multipurpose rig suitable for different kind of drilling application, that can also be easily converted in short mast configuration.

Counterweight Lifting System

This HPM can be assembled by itself without the need of assistant cranes.

This patented feature gives contractors the ability to quickly and easily reduce the overall weight of the rig during the transport phase, making it possible to utilise a standard-sized trailer and reduce then hauling costs and avoids oversize/overweight permits.

Auxiliary House Lock

The operator can make the full use of the whole torque without having the machine swinging from side to side.

This patented feature can be automatic or enabled through a button on the joystick. The enabling of the brake offers increased comfort for the operator as the vibrations when drilling on rock are reduced to almost zero.

Low-headroom Configuration

This HPM can be quickly and safely converted in Short Mast configuration allowing it to work in limited heights job sites, such as under bridges or below power lines.

Comfort Cabin

The HPM cabin is equipped with a comfy and wide adjustable seat. The standard automatic air conditioning keeps the cabin at the ideal temperature throughout the day.

All machine interfaces are ergonomically positioned and designed for optimum control and efficiency. The easy accessible keyboards allow the operator to quickly get the rig ready to drill.

Automatic Functions

Automatic functions allow the operator to reduce rig-up time and get the most in productivity.

With a push of a button, the operator can make use of automatic functions, including: Verticality of the mast, Automatic Rig-up, Automatic return to drilling point and rotary auto drive.

Drilling Cruise Control

The HPM software includes the enabling of the drilling cruise control. When the system is enabled, the operator can preselect the rotary gear so it’s speed. With a push of a button the system can be activated and the operator can also lock the crowd pressure for a complete automatic drilling mode. Safety systems can disable the function immediately.

Remote Control

Increase safety and flexibility when loading or unloading the equipment. The operator can make use of different viewing angles while moving the machine from outside the cabin. Having a complete view of the rig during these phases allows the operator to make sure that hoses, wirings and wire ropes are safely positioned. Drilling functions are enabled through the remote control for a safe service and maintenance of the rig.

Expandable Tracks

The retractable undercarriage allows to reduce width of the machine for transport phases, reducing hauling related costs and avoiding transport permits. Once expanded, the undercarriage provides great stability at any working radius for a 360° drilling capability.

Rotary Gear System

During the working phase, the operator can choose the right rotary rotation speed, having 10 speeds available.

The HPM patented rotary gear control system allows the operator to quickly reach the optimal spin-off speed, with just one click.

Technical data

All data presented refers to the standard model and may vary based on specific equipment configuration and customer requirements.

Need more torque, pull or depth? Contact us to explore the full range of configuration options.

| Base | CAT®330 |

|---|---|

| Engine Type | C7.1 |

| Installed Power | 205 hp275 kW |

| Max. Effective Torque | 185000 ft.lbs251 kNm |

|---|---|

| Working Speed | 9-24 rpm |

| Discharge Speed | 50-120 rpm |

| Main winch pull | 230 kN51700 lbf |

|---|

| Crowd Type | Cylinder Crowd System |

|---|---|

| Max. crowd force | 310 kN70000 lbf |

| Crowd Stroke | 14'6" ft inc4420 mm |

| Drilling Depth | 120' ft36 m |

|---|---|

| Drilling Diameter | 2400 mm8' ft inc |

| Operating Weight | 128300 lbf58200 kg |

|---|---|

| Transport weight | 36500 kg80500 lb |

| Transport width | 3000 mm9'10" ft inc |

| Transport height | 11'6" ft inc3505 mm |